FAST, RELIABLE, SAFE

RUSSELL HPGR TRANSPORTERS

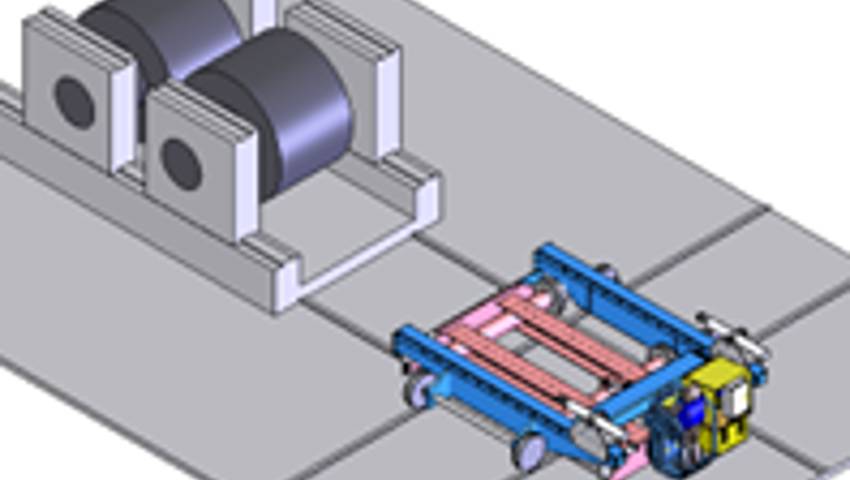

Built for extreme loads, RUSSELL HPGR Transporters ensure precision handling of High Pressure Grinding Rolls. Available up to 110 tonne capacities.

Extraction and replacement of large HPGR 110 tonne rolls cannot be achieved using overhead crane due to obstruction by mill feed chute and other plant structural constraints. HPGR bearings also have minimal tolerance for skew, which can otherwise risk damage to seals and an inflict an additional 24-hours of unplanned downtime. The heavy-weight RUSSELL HPGR Transporter meets these challenges head on. It’s purpose-built to integrate with your plant and extract, transport and replace extreme HPGR loads with high precision, efficiency and safety.

Benefits

- Fit-for-purpose HPGR extraction, transportation and replacement solution

- Eliminates the use of inappropriate cranes and unsafe maintenance methods

- Ensures efficient HGPR refurbishing and minimises plant downtime

- Serves multiple one or multiple HPGR installations for increased asset utilisation

- Protects people, plant and equipment

- Improves site safety and comminution plant availability

ADDITIONAL INFORMATION

-

- Super strong, tough and reliable

- High capacity – capable of lifting HPGR bearings up to 110T

- Laser measurement control system ensures precision docking and accurate bearing alignment

- Available in one and two directional rail solutions

- Two directional RUSSELL HPGR transporters have a two independent chasses, extraction cylinders and drive-wheel system for easy transfer from one set of rails to the other while providing height and level adjustment for each HPGR plant

- One directional RUSSELL HPGR Transporter can be lifted from the rail by maintenance cranes and rotated 180° to allow extraction of HPGR from either side of the plant

- Easy to operate and ensures operator safety

- Robust design and construction, and rigid rail mounting

-

- RUSSELL HPGR Transporters are for extracting, transporting and replacing high pressure grinding roll (HPGR) installations during maintenance operations

- HPGR are being increasingly adopted by comminution plants for their excellent energy efficiency

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs sold and manufactured.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME assets & services.

“With it's Herculean payload capacity of 110T and flexible one and two-directional rail travel, the RUSSELL HPGR Transporter is the fast, reliable, safe choice for high pressure grinding roll (HPGR) refurbs and maintenance.”

Related products

RUSSELL MULTI-WHEEL FEED CHUTE TRANSPORTER

RUSSELL Multi-Wheel FCTs significantly reduce floor point loads with smart load distribution technology. Available up to 100 tonne capacities.

Read More

RUSSELL CLASSIC FEED CHUTE TRANSPORTER

RUSSELL Classic FCTs will take the heavy load of the mill feed, and load off the plant floor, with ease and utmost safety. Available up to 80 tonne capacities.

Read More

RUSSELL RAIL FEED CHUTE TRANSPORTERS

RUSSELL Rail FCTs are field proven to withstand heavy loads and harsh plant conditions. Available up to 80 tonne capacities.

Read More

RME 24/7/SERVICE

RME 24/7/SERVICE ensures Customers have access to trusted OEM engineering know-how when they need it – whether onsite or collaborating online in real-time.

Read MoreOur Experts

Evgeny Klyukin

Business Development Manager, Central Asia/Middle East/Europe/South Asia

Kabelo Mogobye

Regional General Manager, Africa & South Africa, Leadership Team

Owen Flemming

Regional General Manager, North/Central America, Leadership Team

Denny Wisely

Vice President Sales & Business Development, North America