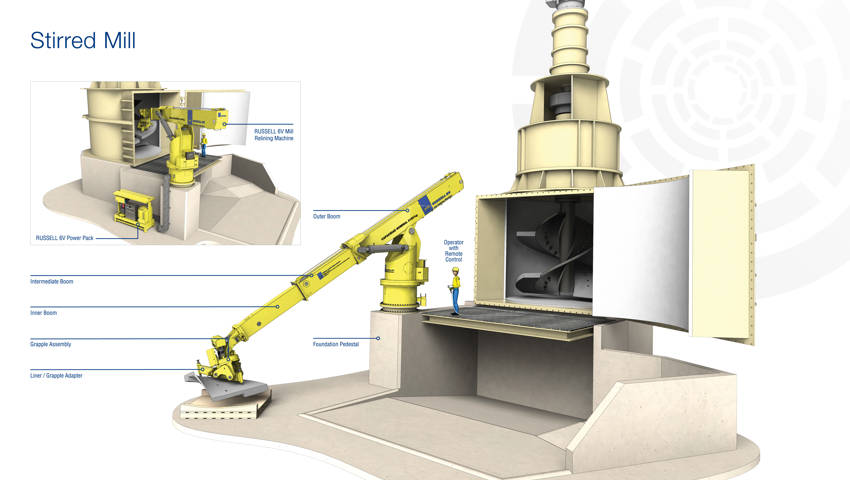

RUSSELL 6V Mill Relining Machine

RUSSELL 6V MRMs are built for heavy-weight auger liner exchange in large vertical axis stirred grinding mills.

Up to 10 tonne capacities.

The RUSSELL 6V Mill Relining Machine (fixed) and RUSSELL 6VM Mill Relining Machine (mobile lift-in) are custom-engineered for lifting, manoeuvring and placing extremely heavy auger liners in large vertical axis stirred grinding mills. When used in conjunction with the included liner removal adapter tools, it also facilitates the lifting of worn liners and removing them from the mill.

Benefits

- Fit-for-purpose liner replacement equipment for large vertical axis stirred grinding mills

- Accurate and safe exchange of large vertical axis stirred grinding mill auger liners

- Frees up the use of other site resources during vertical mill relines

- Eliminates the use of inappropriate cranes and unsafe maintenance methods

- Customised to suit the needs of each large vertical axis stirred grinding mill

- Improves site safety and mill availability

ADDITIONAL INFORMATION

-

- Strong, tough and capable of lifting liner weighing up to 10T

- Comes in two models: The RUSSELL 6V is fixed plant and the RUSSELL 6VM is mobile plant

- Low profile liner interface designed specifically for the vertical axis stirred grinding mills

- RUSSELL 6V’s boom tip fits easily between the pitches of the auger

- Proportional hydraulic control for highly accurate supporting of new auger liner segments

- Remote proportional-control pendant for improved operator safety and machine control

- Robust machine design and integrated rigid machine-to-foundation mounting

- Excellent machine stability and auger liner fitting accuracy

-

- RUSSELL 6V Mill Relining Machine is a fixed MRM for relining large vertical axis stirred grinding mills

- RUSSELL 6VM Mill Relining Machine is a mobile lift-in MRM for relining large vertical axis stirred grinding mills

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs sold and manufactured.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME assets & services.

"The RUSSELL 6V and 6VM Mill Relining Machines are custom-engineered to lift extremely heavy weight auger liners found in large vertical axis stirred grinding mill liners. They are highly proficient, reliable and will exchange liners accurately. Most importantly, they will keep your site's people, plant and equipment safe."

Related products

THUNDERBOLT 250

Lighter in weight but not in impact, the portable, pneumatic THUNDERBOLT 250 Recoilless Hammer helps small mills and field service crews to increase productivity and safety.

Read More

THUNDERBOLT 500

The THUNDERBOLT 500 Recoilless Hammer is our top-of-the-line pneumatic liner bolt removal tool. It packs a punch and eliminates hazardous practices which impact safety.

Read More

RUSSELL RADIO REMOTE JOYSTICK CONTROL

Safe and accurate remote control of your RUSSELL Liner Exchange Machine's every function from anywhere around the mill.

Read More

O-ZONE LINER LIFTING TOOLS

When it’s time to safely, quickly secure and pick up worn liners from the mill charge, RME’s range of O-ZONE Liner Lifting Tools provide a safe alternative for liner transport.

Read More

ANNUAL SERVICING

Relining requires critical attention to safety. Risks increase when harsh conditions and usage impact asset integrity. Ensure annual inspections and servicing are a priority.

Read MoreOur Experts

Evgeny Klyukin

Business Development Manager, Central Asia/Middle East/Europe/South Asia

Kabelo Mogobye

Regional General Manager, Africa & South Africa, Leadership Team

Owen Flemming

Regional General Manager, North/Central America, Leadership Team

Denny Wisely

Vice President Sales & Business Development, North America