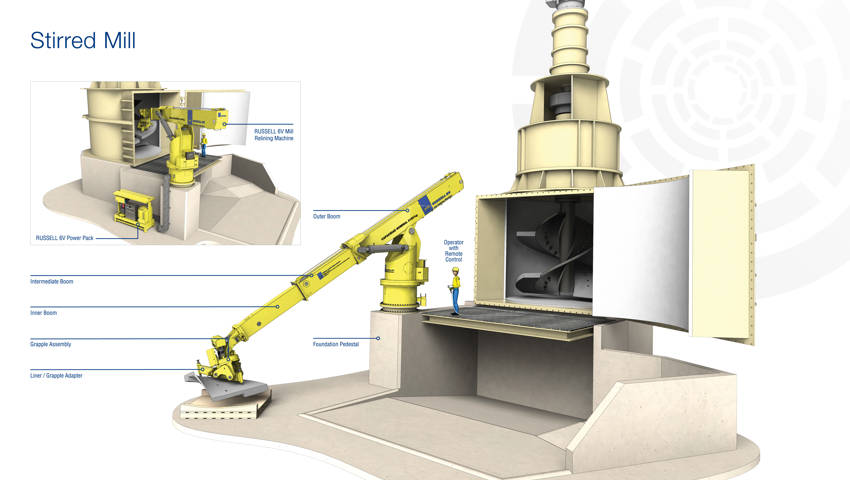

RUSSELL 3V Mill Liner Handler

The RUSSELL 3V Mill Liner Handler is for lifting and manoeuvring liners in vertical axis stirred grinding mills.

Up to 13 tonne capacities.

The RUSSELL 3V Mill Liner Handler is custom-engineered for lifting and manoeuvring auger liners in vertical axis stirred grinding mills. When used in conjunction with the included liner adapter tools it also facilitates the lifting of worn auger liners and removing them from the mill.

Benefits

- Fit-for-purpose auger liner replacement equipment for vertical axis stirred grinding mills

- Eliminates the use of inappropriate cranes and unsafe maintenance methods

- Customised to suit the needs of the vertical axis stirred grinding mill

- Enables faster, safer vertical axis stirred grinding mill liner exchange

- Improves site safety and mill availability

ADDITIONAL INFORMATION

-

- Strong, tough and capable of lifting auger liners weighing up to 13T

- Low profile liner interface designed specifically for the vertical axis stirred grinding mills

- RUSSELL 3V’s boom tip fits easily between the pitches of the auger

- Proportional hydraulic control for highly accurate supporting of new auger liner segments

- Remote proportional-control pendant for improved operator safety and machine control

- Robust machine design and integrated rigid machine-to-foundation mounting

- Excellent machine stability and auger liner fitting accuracy

-

- RUSSELL 3V Mill Liner Handler is for lifting and manoeuvring new and worn auger liners in vertical axis stirred grinding mills.

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs sold and manufactured.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME assets & services.

"The RUSSELL 3V is an extremely high-capacity, purpose-built three axis vertical mill liner handler. It offers fast, reliable and safe exchange of new and worn auger liners in vertical axis stirred grinding mills."

Related products

THUNDERBOLT MAGNUM 2000

The mighty THUNDERBOLT MAGNUM 2000 is the industry’s most powerful recoilless hammer, delivering the ultimate in impact energy per blow.

Read More

THUNDERBOLT MAGNUM 1000

The THUNDERBOLT MAGNUM 1000 is the industry's most productive hammer yet. It's high-energy rapid-fire rate will shorten knock-in times and improve operator safety.

Read MoreOur Experts

Evgeny Klyukin

Business Development Manager, Central Asia/Middle East/Europe/South Asia

Kabelo Mogobye

Regional General Manager, Africa & South Africa, Leadership Team

Owen Flemming

Regional General Manager, North/Central America, Leadership Team

Denny Wisely

Vice President Sales & Business Development, North America