RUSSELL 3/7-E 1500 Hybrid MLH/MRM

Can be either – a 3-axis handler that evolves to a 7-axis MRM – to advance relining speed and safety.

1500 kg capacity

The RUSSELL 3/7 Model E 1500 Hybrid Liner Exchange Machine can be economically purchased as a RUSSELL 3-axis Mill Liner Handler with future upgradability to 7-axis liner placement functionality. It is ideal for small to medium sized mills with liners up to 1500kg and sufficient free space at one end of the mill for machine-into-mill entry access. It is ideal for operators of mills who want a safe, reliable, cost-efficient and future-proofed solution that reduces mill reline duration and is backed by RME’s superior after-sales service.

Benefits

- Renowned RUSSELL machine quality and after-sales service at an economical entry price and fast delivery

- Future-proofed with upgradability from 3-axis liner suspension to 7-axis liner placement capability

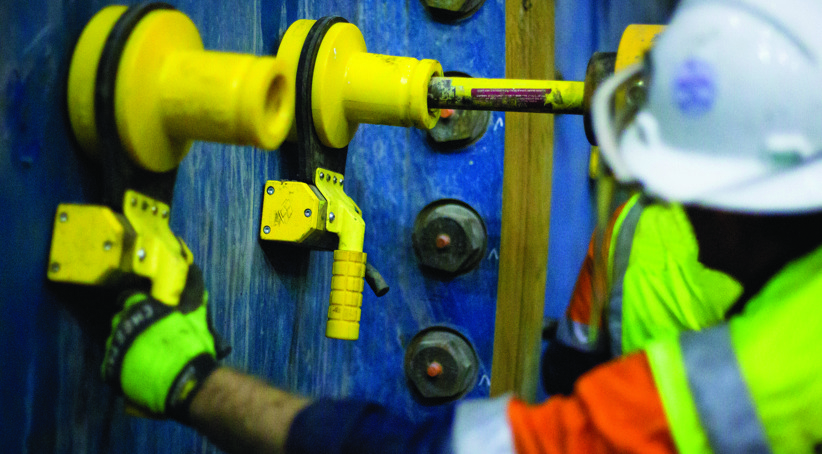

- Safety optimisation potential through upgrading from liner slinging functionality to secure, pinned liner engagement

- Conveniently re-uses existing mill floor tie-down details in many circumstances.

- Opportunity to optimise liner design, and use larger, fewer pieces for faster liner exchange and shorter shutdowns

- Enables safe relining of smaller SAG and Ball mills through elimination of repetitive and high-risk manual lifting

ADDITIONAL INFORMATION

-

- Telescopic boom and liner rigging hook, supported by slewing turntable, for reaching all liners in the mill in 3-axis liner suspension operation

- ‘Sling-To-Place' Upgrade Kit replaces telescopic boom with new telescopic boom and liner placement grapple for 7-axis liner placement functionality, for reaching and precise placing of all liners in the mill

- Single or two-piece beam for robust and safe support of the slewing turntable and boom

- Versatile machine control options with either ergonomic operator’s seating and integrated machine control or comfortable radio remote control unit for mills with tight entries

- Powered liner cart providing efficient and safe transport of new and worn liners into and out of the mill

- Machine travel facilitated by steerable rubber-tyred wheels or rail wheels.

- On-board Hydraulic Power Pack that delivers reliable hydraulic and electrical power.

- Liner lifting capacity of 1500kg

-

- Sites who desire the commercial and functional flexibility of this upgradable machine

- RUSSELL 3 1500 is suitable for applications beyond the RUSSELL 3 1000 capacity limit

- Expertly-engineered for sites where there is sufficient manoeuvring space outside the mill

- Typically available for mills 13ft to 28ft (4m to 8.5m) in diameter and 12ft to 30ft (3.6m to 9m) in length

- Minimum clear entry diameter required is typically 3.8ft (1155mm)

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs sold and manufactured.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME assets & services.

"The RUSSELL 3/7 Model E 1500 hybrid liner exchange machine is an exciting and innovative approach for mill operators who want RUSSELL quality and appreciate the upgradability of this novel machine, from 3-axis liner suspension to 7-axis liner placement functionality. This new configuration is another way we are working to ensure the fast, reliable, safe RME Mill Relining System is accessible to every site.”

RUSSELL 7 COMPARISON

RUSSELL 7-R MRM |

RUSSELL 7-S+ MRM |

RUSSELL 7-S MRM |

RUSSELL 3/7 – ENE MLH/MRM |

|

|---|---|---|---|---|

CAPACITY (KG) |

4500 – 9000 |

4500 – 9000 |

2500 – 9000 |

1500 |

AXIS OF MOVEMENT (#) |

7 |

7 |

7 |

3/7 |

AUTOMOTION (Robotic Operating System) |

Fully-operational |

Hardware-equipped |

Upgrade-ready |

No |

LINER VISUAL DETECTION CAMERA |

Fully-operational |

Hardware-equipped |

Upgrade-ready |

No |

MOTOR |

Dual WEG W22 |

Dual WEG W22 |

Single WEG W22 |

Single WEG W22 |

AUTOMATED PARK / DEPLOY |

Fully-operational |

Fully-operational |

Upgrade-ready |

No |

GRAPPLE OPTIONS |

RUSSELL All Reach Grapple Standard |

HKS / Cylinder |

All Reach / HKS / Cylinder / Small Entry |

HKS / Cylinder |

TIE-DOWN SAFETY INTERLOCK |

Standard |

Standard |

Standard |

No |

Related products

THUNDERBOLT MAGNUM 1000

The THUNDERBOLT MAGNUM 1000 is the industry's most productive hammer yet. It's high-energy rapid-fire rate will shorten knock-in times and improve operator safety.

Read More

THUNDERBOLT MAGNUM Mobile Jib

The THUNDERBOLT MAGNUM Mobile Jib is our highest reaching jib and tailor-made to ensure hammers are suspended safely and perform superbly.

Read More

THUNDERBOL T-MAG MOIL ACCESS GUIDES

T-MAGs are designed for use with THUNDERBOLT Recoilless Hammers to make liner bolt knock-in safer and more efficient, and protect the mill shell.

Read More

O-ZONE LINER LIFTING TOOLS

When it’s time to safely, quickly secure and pick up worn liners from the mill charge, RME’s range of O-ZONE Liner Lifting Tools provide a safe alternative for liner transport.

Read MoreOur Experts

Evgeny Klyukin

Business Development Manager, Central Asia/Middle East/Europe/South Asia

Owen Flemming

Regional General Manager, North/Central America, Leadership Team