RUSSELL 3-L 1000 MLH

Giving smaller mills the certainty of RME quality and reliability, with the means to improve safety and mill availability.

1000 kg capacity.

The RUSSELL 3 1000 Mill Liner Handler gives smaller mills the certainty of industry-best quality and reliability with the means to significantly improve mill availability and safety. Robust to handle liners up to 1000kg and a minimal footprint outside the mill, the RUSSELL 3 is field-proven as a safer and affordable mechanised mill relining solution.

Benefits

- Opportunity to optimise liner design

- Enables safe relining of smaller SAG and Ball mills

- Eliminates repetitive and high-risk manual lifting

- Efficient and safe transport of new and worn liners via a powered liner cart

- Customised to suit the needs of each unique site for liner weight, concentratorplant configuration, mill type and size

- RME’s quality Asset Support solutions maximise asset performance andproductivity throughout mill life cycle

ADDITIONAL INFORMATION

-

- Three-axis liner suspension crane mechanism for fast, reliable, safe operation

- Liner lifting capacity up to 1000kg

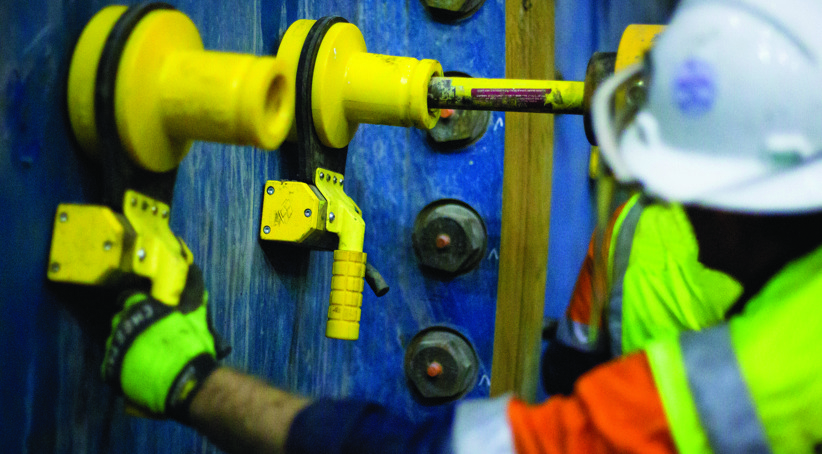

- Fixed rigging eye for use with liner lifting slings and RME’s O-ZONE liner lifting tools

- Options for machine movement include a lift in/lift out base, Single Direction Rail or Rubber-Tyred 3 x 1 (three wheels with one driven wheel)

- Telescopic beam (depending on mill size)

- Faster and safer transport of worn and new liners via a powered liner cart or powered roller conveyor

- Ergonomic operator seat and controlsSupplied with the THUNDERBOLT

- Hydraulic Power Pack that delivers powerful, reliable and precise operator control

- Engineered and manufactured to order for liner design and weight, plant layout, mill type and size

- Supported by RME Site Services & Optimisation through commissioning, training and service life to maximise asset performance and productivity

-

- Available for mills 10ft to 28ft in diameter and 12ft to 30ft in length

- Accesses mill from the feed end where there is a minimum clear entry diameter of 800mm

- Offers an efficient and safe mechanised mill relining solution for smaller SAG and Ball mills with liners between 400kg and 1000kg

- Ideal for sites serviced by manual relining that are beyond the capacity of RME’s MILLMAST Mill Liner Handlers, but don’t have the plant space or mill economics to procure a RUSSELL MRM

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs sold and manufactured.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME assets & services.

"The RUSSELL 3 1000 is a three-axis Liner Handler for small to medium sized mills and suits those applications beyond the MILLMAST Powershift Liner Handler 400kg capacity limit, at sites where there are no space limitations outside the mill."

Related products

THUNDERBOLT MAGNUM 1000

The THUNDERBOLT MAGNUM 1000 is the industry's most productive hammer yet. It's high-energy rapid-fire rate will shorten knock-in times and improve operator safety.

Read More

THUNDERBOLT MAGNUM Mobile Jib

The THUNDERBOLT MAGNUM Mobile Jib is our highest reaching jib and tailor-made to ensure hammers are suspended safely and perform superbly.

Read More

THUNDERBOL T-MAG MOIL ACCESS GUIDES

T-MAGs are designed for use with THUNDERBOLT Recoilless Hammers to make liner bolt knock-in safer and more efficient, and protect the mill shell.

Read More

O-ZONE LINER LIFTING TOOLS

When it’s time to safely, quickly secure and pick up worn liners from the mill charge, RME’s range of O-ZONE Liner Lifting Tools provide a safe alternative for liner transport.

Read MoreOur Experts

Evgeny Klyukin

Business Development Manager, Central Asia/Middle East/Europe/South Asia

Owen Flemming

Regional General Manager, North/Central America, Leadership Team