THUNDERBOLT 500

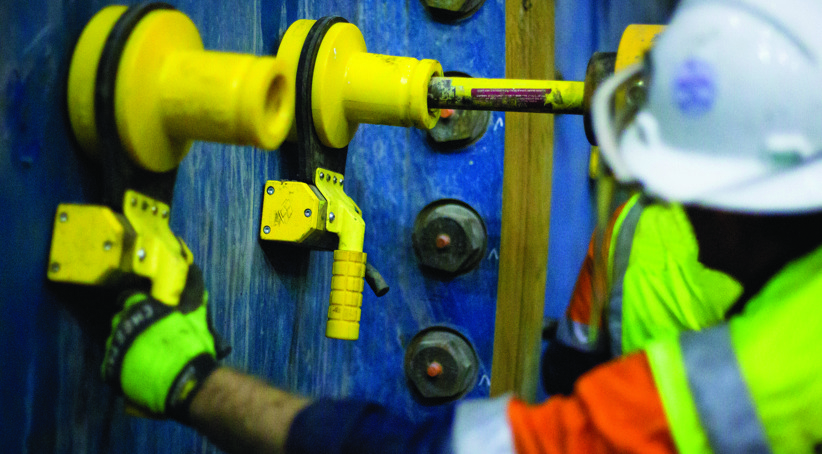

The THUNDERBOLT 500 Recoilless Hammer is our top-of-the-line pneumatic liner bolt removal tool. It packs a punch and eliminates hazardous practices which impact safety.

The THUNDERBOLT 500 Recoilless Hammer is the industry’s top-of-the-line pneumatic liner bolt removal tool. Gone are the days of sledge hammer miss swings and glancing blows, this hammer generates a precise 500 joules every second consistently. Ideal for small and mid-capacity mills, the THUNDERBOLT 500 will straightaway boost safety and mill availability.

Benefits

- Precision-engineered mechanically-integrated solution

- Pneumatic-powered for safe operation in hazardous locations

- Industry-leading robustness and reliability

- Low maintenance needs and total lifecycle costs

- Eliminates dangerous manual tasks, ensures operator safety

- Improves reline productivity for higher mill availability

ADDITIONAL INFORMATION

-

- Pneumatic-powered, plug-n-go, worn liner bolt removal solution

- Delivers an unwavering 500 joules of impact, 60 times a minute

- Recoilless design minimises operator fatigue and maximises safety

- Built-in safety mechanisms to prevent accidental discharge

- Air intensifier for optimal hammer performance irrespective of plant air pressure

- On-board blow counter monitors usage for preventative maintenance planning

- Time-proven precision engineering and parts manufacturing ensure low wear and tear and extended service life

- Air regulator ensures optimal, predictable hammer firing performance

- Crane lifting lugs and forklift tyne pockets for easy transportation around mill circuits

- Mechanically-integrated components – air intensifier, hammer, hose reel, moils – for space-efficient, secure storage between relines

-

- Ideal for small to mid-capacity mills, particularly those still serviced by manual sledge hammering and battering rams

- Suitable for use in environments where electrical tools are a potential hazard

- A flexible companion to hydraulic-powered THUNDERBOLT 750 and 1500 SP Recoilless Hammer fleets

- RME stands ready to guide Customers through the THUNDERBOLT selection process for their mill requirements

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs engineered, manufactured and delivered.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME equipment & services.

"The THUNDERBOLT 500 is undeniably the reline industry’s highest performing air powered recoilless hammer. Not only does it pack a punch during knock-in, but it puts an emphatic end to unsafe liner bolt removal processes which impact the health and safety of your crew."

THUNDERBOLT Recoilless Hammer Model Comparison

THUNDERBOLT MODEL |

MAGNUM 2000 |

MAGNUM 1000 |

1500 SP |

750 SP |

500 |

250 |

|---|---|---|---|---|---|---|

POWER |

Hydraulic |

Hydraulic |

Hydraulic |

Hydraulic |

Pnuematic |

Pnuematic |

JOULES PER BLOW |

2000 – EN MAGNUM Mode 1500 – Standard Mode |

1000 – MAGNUM Mode 750 – Standard Mode |

1500 |

750 |

500 |

250 |

BLOWS PER MINUTE |

70 – MAGNUM Mode 80 – Standard Mode |

140 – MAGNUM Mode 160 – Standard Mode |

60 |

90 |

60 |

60 |

SERVICE INTERVALS |

100,000 Blows or every two (2) years |

100,000 Blows or every two (2) years |

40,000 Blows or Annually |

40,000 Blows or Annually |

40,000 Blows or Annually |

Annually |

Related products

THUNDERBOLT MOBILE Elbow Jib

The pneumatic-powered THUNDERBOLT Mobile Elbow Jib is a perfect partner for the THUNDERBOLT 500 Recoilless Hammer. It’s safe, versatile, and will raise your productivity.

Read More

THUNDERBOL T-MAG MOIL ACCESS GUIDES

T-MAGs are designed for use with THUNDERBOLT Recoilless Hammers to make liner bolt knock-in safer and more efficient, and protect the mill shell.

Read MoreOur Experts

Evgeny Klyukin

Business Development Manager, Central Asia/Middle East/Europe/South Asia

Kabelo Mogobye

Regional General Manager, Africa & South Africa, Leadership Team

Owen Flemming

Regional General Manager, North/Central America, Leadership Team

Denny Wisely

Vice President Sales & Business Development, North America