THUNDERBOL T-MAG MOIL ACCESS GUIDES

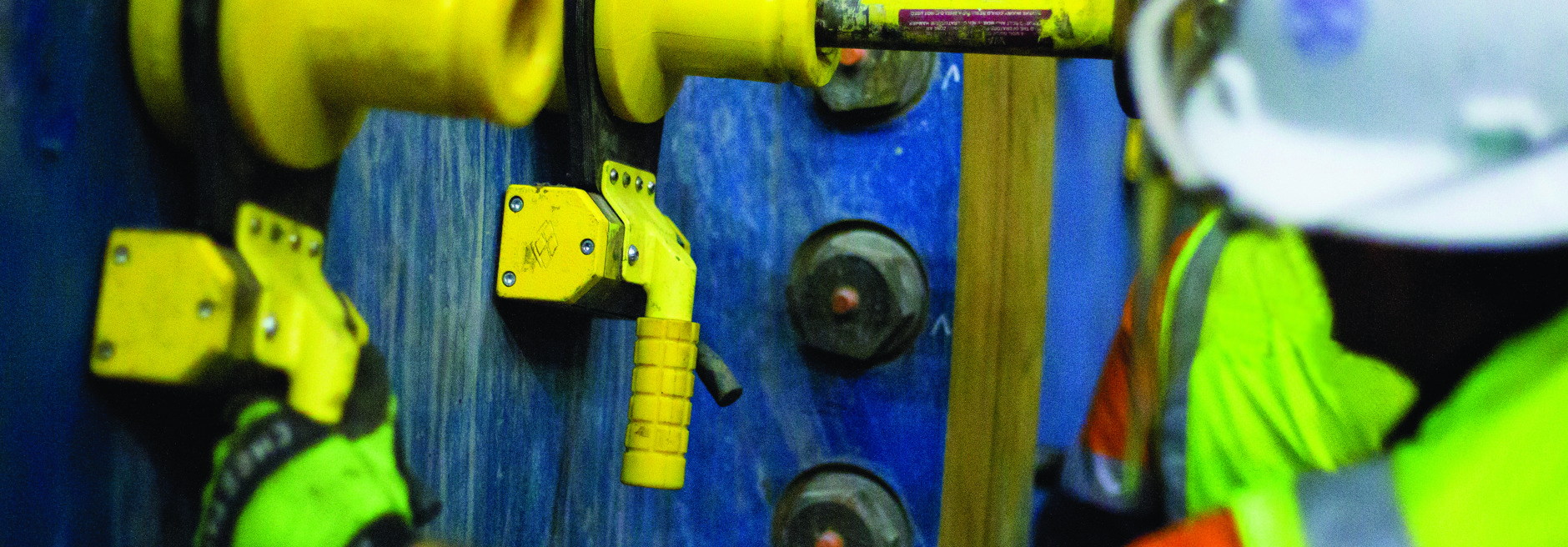

T-MAGs are designed for use with THUNDERBOLT Recoilless Hammers to make liner bolt knock-in safer and more efficient, and protect the mill shell.

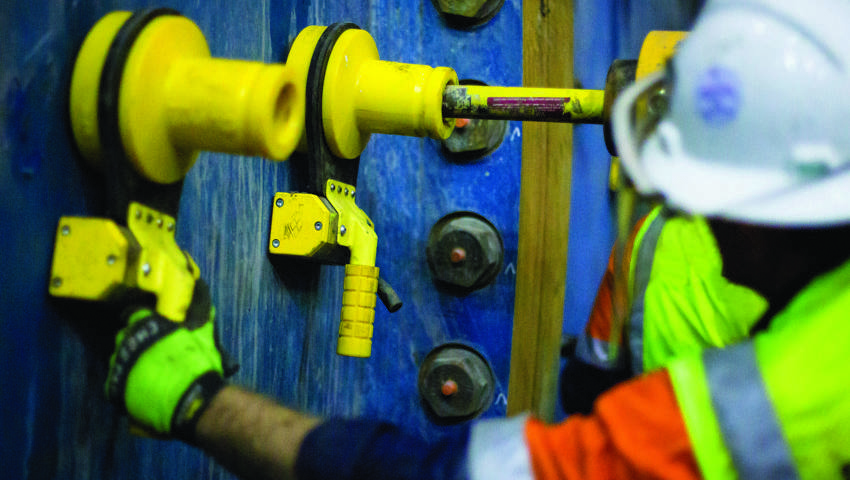

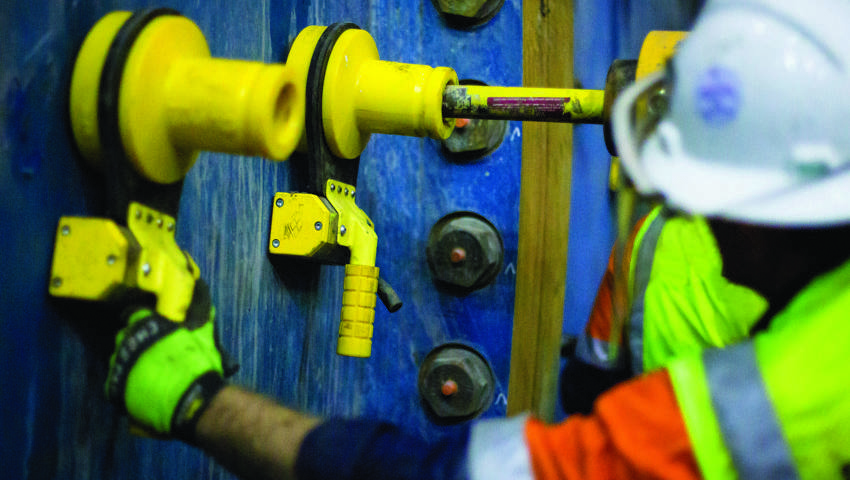

The THUNDERBOLT T-MAG Moil Axis Guide (T-MAG) is ergonomically designed for use with THUNDERBOLT Recoilless Hammers to make liner bolt knock-in safer and more efficient. With a powerful magnet that adheres temporarily to the mill shell, the innovative T-MAG eliminates the need for additional personnel in the THUNDERBOLT Hammer strike zone, and ensures fast, reliable and safe relines.

BENEFITS

- Eliminates handheld moil guides for greater efficiency.

- Magnetised attachment reduces injury risks and improves reline safety.

- Precision engineered to extend moil and bolt life, reducing equipment costs.

- Minimises shell and bolt hole damage.

- Higher levels of operator safety in hazardous areas.

ADDITIONAL INFORMATION

-

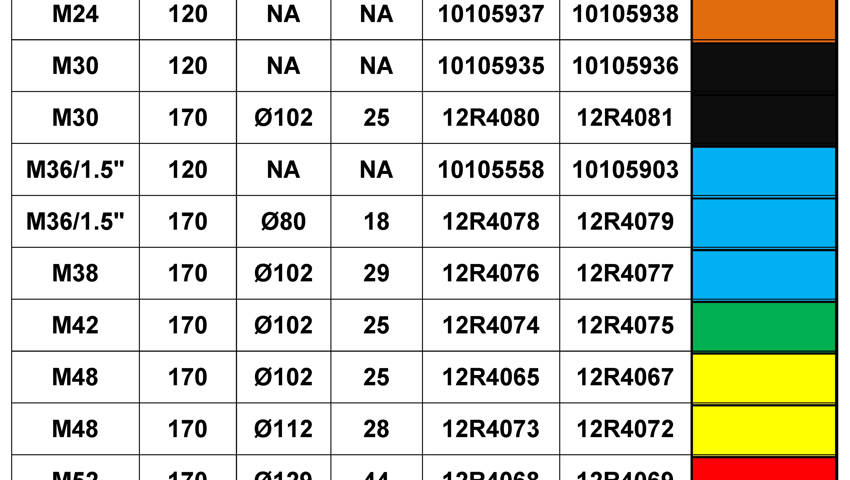

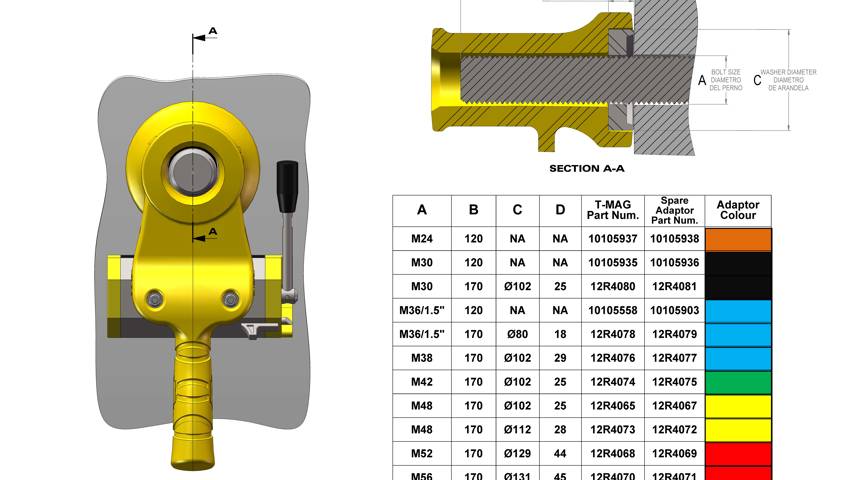

- Range of T-MAGs available to suit most liner bolts based on bolt diameter, length of bolt protruding mill shell, and washer use, diameter and thickness

- Targeted, consistent bolt strikes enable swifter, more efficient bolt removal and improved reline times

- Protects the operator’s eyes, face and other vulnerable body from metal shards from incorrectly aligned THUNDERBOLT Hammer use possible without T-MAGs

- Moil guide body is made of high-wearing, rigid polyurethane

- Powerful magnets allow the T-MAGs to ‘stick’ to the shell, and can be easily removed and repositioned

- T-MAGs magnets can be switched on and off for easy manipulation

- The T-MAG adds another level of safety and productivity to mill operations, to get the best equipment investment

-

- T-MAGs are most effectively used in sets, with a recommended quantity of four T-MAGs per THUNDERBOLT Hammer

- T-MAG use builds upon the results Customers are already achieving with the THUNDERBOLT Hammer

- RME provides certified training in the use of THUNDERBOLT Hammers and accessories

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs engineered, manufactured and delivered.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME assets & services.

"The T-MAG has been extensively tested in the field and at our Product Development centre. The data collected showed a reduction in mill bolt removal times by up to 5 hours on high wear relines of large mills and up to 3 hours on medium mills. The time saving increases when more Hammers are utilised for liner bolt knock-in."

Related products

RUSSELL LINER LEVER

Remove crew from hazardous fall zones with fast and safe removal of stuck worn liners and rubber backing remnants from the mill shell.

Read More

RUSSELL RADIO REMOTE JOYSTICK CONTROL

Safe and accurate remote control of your RUSSELL Liner Exchange Machine's every function from anywhere around the mill.

Read More

THUNDERBOLT STORAGE BOX

Secure, rugged and durable, the THUNDERBOLT Hammer Storage Box offers fast and easy tool access when it’s time to reline.

RUSSELL MILLBRITE IN-MILL LIGHTING

RUSSELL MILLBRITE In-Mill Lighting will improve reline safety and productivity with its simple operation and near-daylight visibility.

Read More