RUSSELL LINER LEVER

Remove crew from hazardous fall zones with fast and safe removal of stuck worn liners and rubber backing remnants from the mill shell.

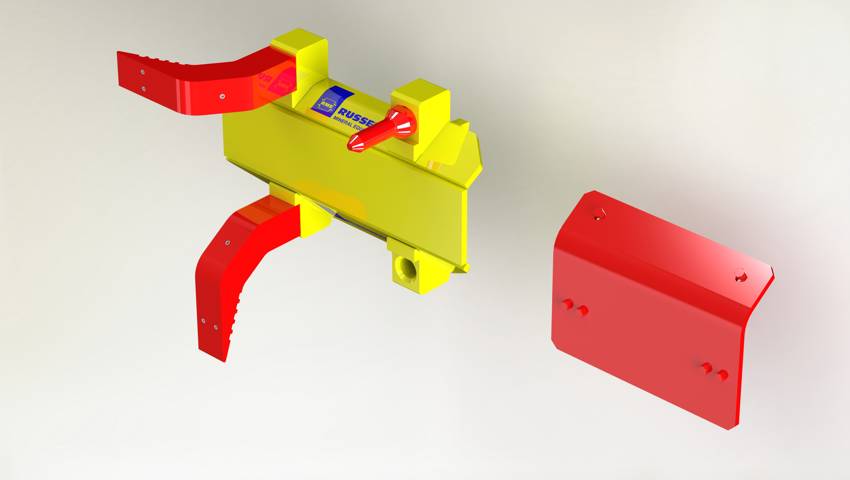

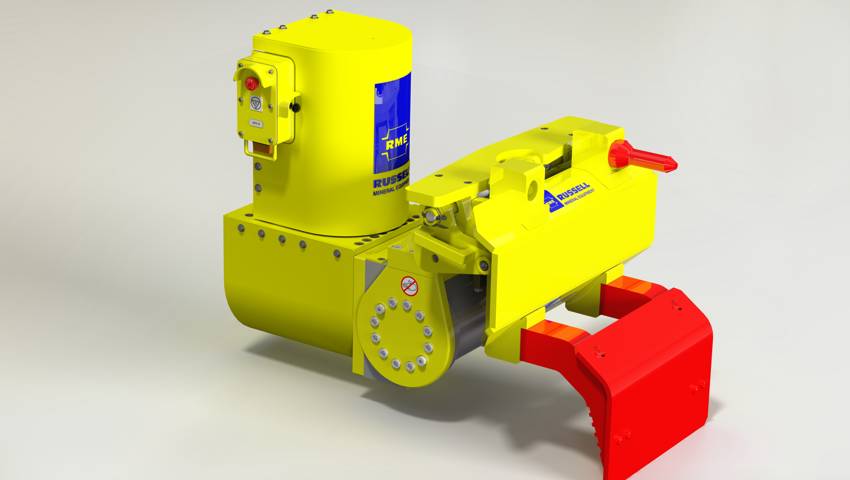

The RUSSELL Liner Lever™ securely attaches to the RUSSELL Mill Relining Machine (MRM) grapple to improve overall equipment effectiveness and crew safety during the high risk ‘knock-in/mucking out’ process.

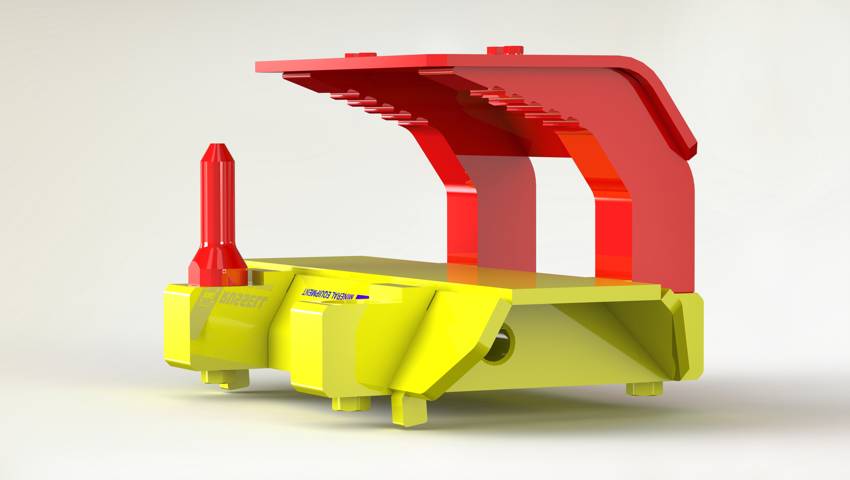

This configurable RUSSELL MRM accessory combines the practical power of multiple point tools – pry bar levers, pickers and scrapers – into a highly versatile integrated unit. The RUSSELL Liner Lever makes it faster and easier to remove worn liners, assists the reduction in mill downtime and protects the RUSSELL MRM grapple from unnecessary damage.

BENEFITS

- Safely removes crews from the dangerous fall zone during worn liner removal.

- Faster and easier removal of worn liners and rubber backing remnants.

- Avoids risk of machine damage due to common reline practices that exceed the machines operating parameters.

- Engineered-to-order to suit each unique RUSSELL MRM and mill environment.

- Custom manufactured for strength, toughness, impact resistance and durability.

- Speeds up manual processes for faster relines reduced downtime and increased mill availability.

ADDITIONAL INFORMATION

-

- Highly-versatile tool which enables the RUSSELL MRM grapple head to manipulate, pin into and pick up

- Triple functionality with multiple crow or pry bars, pickers and scraper plates for worn liner removal tasks and applications

- Ultimate flexibility to configure the unit before attaching it to the RUSSELL MRM

- Improves equipment capabilities and extends life of primary RUSSELL MRM asset

- Custom manufactured to meet RUSSELL MRM technical specifications

- Pairs seamlessly with the grapple on RME’s flagship RUSSELL MRMs

- Delivers the same range and degrees of motion being closely- coupled to the hydraulic grapple

- Expertly handles high-impact and heavyweight loads without damage to the grapple

- Provides a practical alternative to incorrect use of the RUSSELL MRM grapple and minimises repair costs

-

- Reduces safety risk and improves performance when prising stuck liners

- Heavy-duty multipurpose RUSSELL Liner Lever improves overall equipment effectiveness by stripping the rubber backing remnants from the mill shell to complete the clean-up operation

- Eliminates the need for crews to be exposed to unattached liners, or in hard to see/blind spot areas at the front of the machine

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs engineered, manufactured and delivered.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME assets & services.

"The RUSSELL Liner Lever is an essential piece of equipment that makes an incredible impact on relining safety and performance. It’s helping our Customers to substantially reduce reline time, reduce exposure to risk and preserve their critical RUSSELL MRM asset from damage."

Related products

O-ZONE LINER LIFTING TOOLS

When it’s time to safely, quickly secure and pick up worn liners from the mill charge, RME’s range of O-ZONE Liner Lifting Tools provide a safe alternative for liner transport.

Read More

RUSSELL CLAW

Introducing the RUSSELL Claw™ – the new master of muck-out. It eliminates hazardous manual liner slinging, enabling worn liner removal with no crew on the charge. Lifting capacity up to 8000 kg.

Read More

RUSSELL CHARGE ACCESS

RUSSELL CHARGE ACCESS is a safety solution, installed by dropping over the liner cart rail. It provides easy access to the charge from the RUSSELL Mill Relining Machine.

Read More

RME BOLTBOSS

RME BOLTBOSS is an innovative universal toolset that enables safer securing of liners, nuts and bolts from the mill’s exterior without the need for crew to be inside.

Read MoreSS&O Sales Team

Owen Flemming

Regional General Manager, North/Central America, Leadership Team

Denny Wisely

Vice President Sales & Business Development, North America

Manuel Galvez

Regional General Manager, South America, Leadership Team