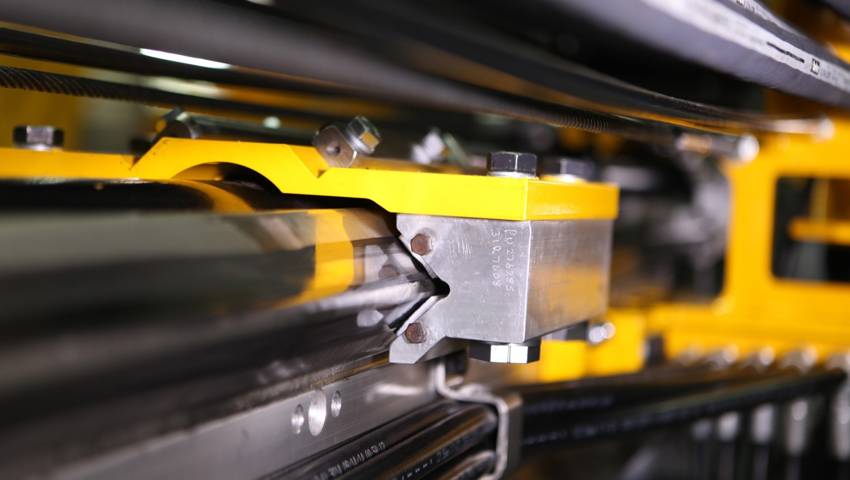

MANAGE DOWNTIME RISK

CRITICAL SPARES PROVISIONING

Balancing varied wear rates, usage and demand with service life and inventory makes critical spares provisioning challenging. RME brings visibility and certainty to this process.

Balancing equipment service level, inventory costs, varied usage and intermittent demand can make the planning of wear parts and critical spares inventory management for your mill relining equipment challenging.

However this is where RME’s OEM expertise steps in to help.

With our 35+ year history of supply to mine sites globally, we know the trends in component life, expected operation, forces under load, equipment condition, and maintenance history, across a wide range of plant environments.

This gives us superior data-driven insight into component wear and part criticality.

Armed with this intelligence, our asset support team can give informed advice to Customers on what the right parts are and when they should be in your onsite inventories.

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs engineered, manufactured and delivered.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME equipment & services.

“The goal of critical or insurance spares is to manage the risk of unplanned downtime. However, these investment decisions can entail a fair degree of uncertainty. RME has a long history of equipment supply to mine sites globally, so we have data-driven insights into wear rates and component criticality. Armed with this intelligence, we help you plan and strike the right balance between performance, cost, risk and safety.”

SS&O Sales Team

Owen Flemming

Regional General Manager, North/Central America, Leadership Team

Denny Wisely

Vice President Sales & Business Development, North America

Lyle Hobbs

Service Account Manager, North America

Manuel Galvez

Regional General Manager, South America, Leadership Team