THUNDERBOLT 750 SP

A field favourite, the THUNDERBOLT 750 Special Performance Recoilless Hammer is highly regarded for its versatility, work-rate, responsive handling and RME reliability.

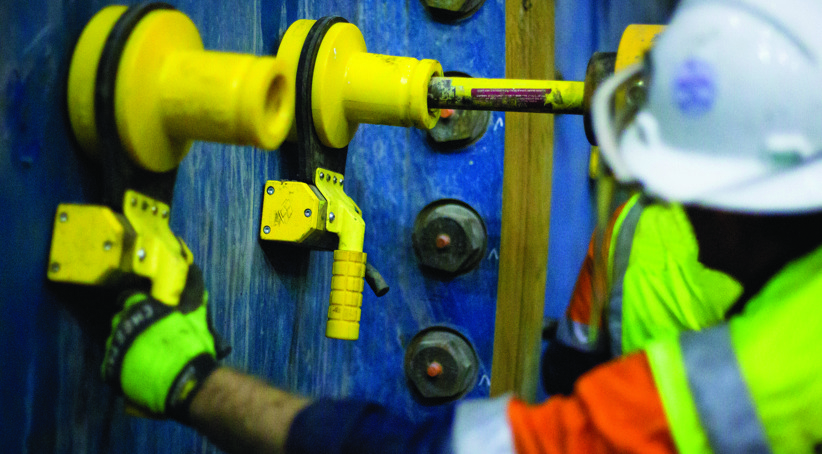

A firm field favourite, the THUNDERBOLT 750 Special Performance (SP) Recoilless Hammer is proven to expedite worn-liner bolt removal and improve operator safety. Highly-regarded for its versatility and reliability, this high-momentum hammer delivers a precise 750 joule strike 90 times per minute, and because of this, is a sought after solution for mills large, medium and small.

Benefits

- Accelerated knock-in work-rate compared to 1500

- Best-in-industry quality, reliability and longevity

- Superior maintainability and lower lifecycle costs

- Reduced operator stress and fatigue

- Eliminates dangerous practices, improves reline safety

- Higher mill availability and mine site profitability

ADDITIONAL INFORMATION

-

- Delivers an unyielding 750 joules of impact 90 times a minute

- Expertly-engineered to ensure minimal recoil to the operator when firing

- Safety observer pendant to prevent accidental firing

- Two-handed trigger mechanism for safer handling and operation

- Electronic operator interface for observing hammer performance and controlling fire timing

- ‘Onboard’ - Condition monitoring in hydraulic unit on usage and unexpected operation avoids unplanned stoppages and aids preventative maintenance

- Accommodates any site-specific standard three-phase power supply

- Upgraded hydraulic and electrical cooling systems for extended equipment life

- Intuitive, integrated on-board hammer controls for the THUNDERBOLT Mobile Jib and Winch

-

- Industry-proven performance across a wide range of mill sizes – small, medium and large

- Suitable for Customers wishing to bolster their existing THUNDERBOLT 750 SP and THUNDERBOLT 1500 SP fleets for streamlined servicing and parts management

- Safe and powerful replacement for manual sledge hammers, battering rams and unfit-for-purpose tools

- Buy backs, trade-ins and reconditioned solutions available

- RME stands ready to guide Customers through the THUNDERBOLT selection process for their mill requirements

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs engineered, manufactured and delivered.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME equipment & services.

"THUNDERBOLT Recoilless Hammers are, without a doubt, a cut above the rest and the THUNDERBOLT 750 SP is no exception to this rule. Renown for its responsive handling and delivering a perfect balance of power and productivity, the THUNDERBOLT 750 SP is a reliable partner for accelerating knock-in speed and safety."

THUNDERBOLT Recoilless Hammer Model Comparison

THUNDERBOLT MODEL |

MAGNUM 2000 |

MAGNUM 1000 |

1500 SP |

750 SP |

500 |

250 |

|---|---|---|---|---|---|---|

POWER |

Hydraulic |

Hydraulic |

Hydraulic |

Hydraulic |

Pnuematic |

Pnuematic |

JOULES PER BLOW |

2000 – EN MAGNUM Mode 1500 – Standard Mode |

1000 – MAGNUM Mode 750 – Standard Mode |

1500 |

750 |

500 |

250 |

BLOWS PER MINUTE |

70 – MAGNUM Mode 80 – Standard Mode |

140 – MAGNUM Mode 160 – Standard Mode |

60 |

90 |

60 |

60 |

SERVICE INTERVALS |

100,000 Blows or every two (2) years |

100,000 Blows or every two (2) years |

40,000 Blows or Annually |

40,000 Blows or Annually |

40,000 Blows or Annually |

Annually |

Related products

THUNDERBOLT Hydraulic Mobile and Fixed Jibs

THUNDERBOLT Hydraulic Mobile Jib and Fixed Jibs are a quality choice for THUNDERBOLT 1500 and 750 suspension.

Read More

THUNDERBOL T-MAG MOIL ACCESS GUIDES

T-MAGs are designed for use with THUNDERBOLT Recoilless Hammers to make liner bolt knock-in safer and more efficient, and protect the mill shell.

Read MoreOur Experts

Evgeny Klyukin

Business Development Manager, Central Asia/Middle East/Europe/South Asia

Kabelo Mogobye

Regional General Manager, Africa & South Africa, Leadership Team

Owen Flemming

Regional General Manager, North/Central America, Leadership Team

Denny Wisely

Vice President Sales & Business Development, North America