FAST, RELIABLE, SAFE

MILL RELINING SYSTEMS

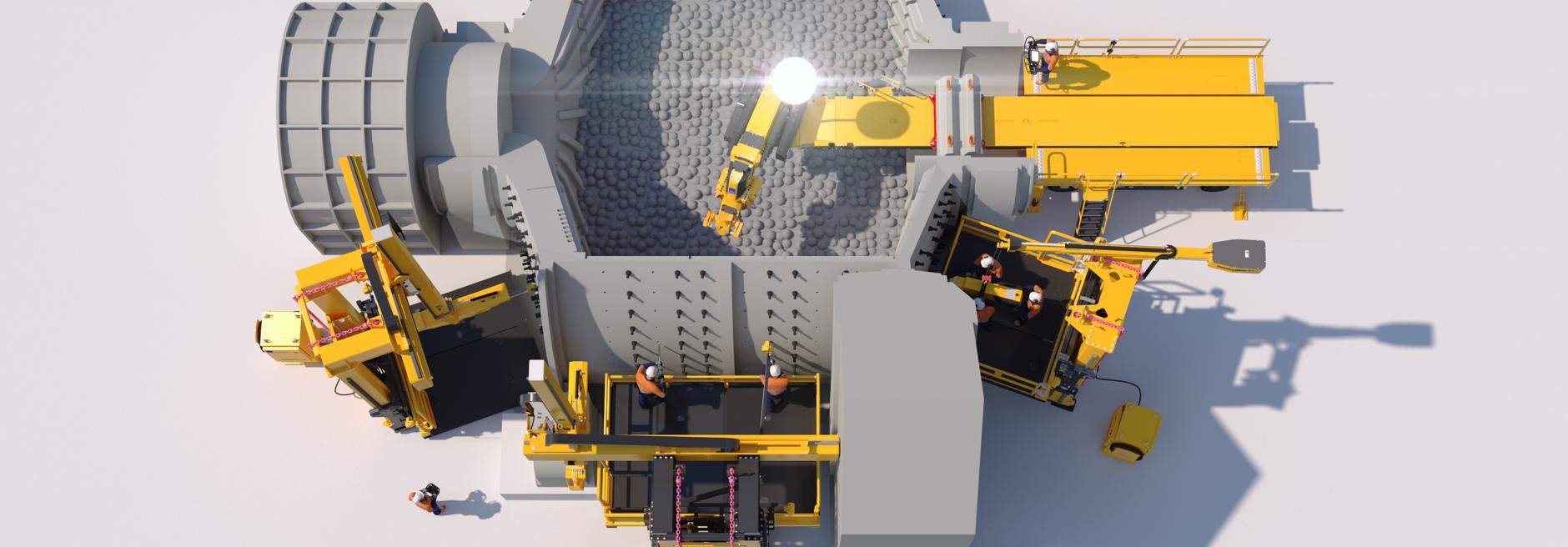

The RME Mill Relining System is the preferred choice for mill operators globally. And now it is ready for an even faster, safer automated future.

Welcome to the RME Mill Relining System

For 40+ years, RME has led the world in the engineering of fast, reliable, safe technologies and processes for every step on the mill relining path. Now, today the integrated RME Mill Relining System has advanced to incorporate autonomous capabilities.

At it’s centre are the trusted RUSSELL Liner Exchange Machines – now with an expanded range for mills large and small – and a modular future-proofed platform for robotised RME AutoMotion™ optionality. Supporting it, are the proven THUNDERBOLT Worn Liner Removal solutions and innovative INSIDEOUT™ Technology.

Together, they move operators out of harm's way and relining off the shutdown critical path.

Best of all, our carefully-staged systems engineering means mines of all sizes can deploy the base components and advance their relining at their own pace – safely.

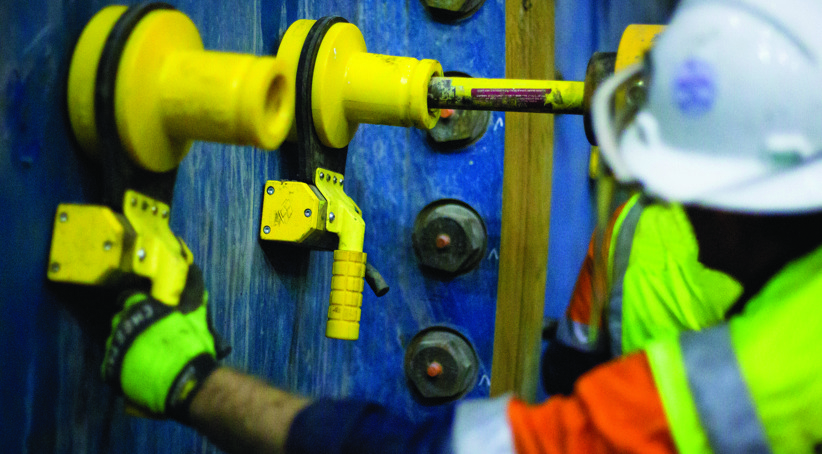

LINER BOLT REMOVAL

Since 1997, THUNDERBOLTs have revolutionised liner bolt removal time and safety. See the wider range and their new faster, safer semi-automated capabilities.

Read More

RUSSELL LINER EXCHANGE MACHINES

The trusted choice for mill operators globally. Our expanded, higher-performing range – from <400 kg to 10 tonne capacities – ensures fast, reliable, safe mill relining is available to every mine site.

Read More

TRANSPORTERS

Built to work over the long haul, RUSSELL Feed Chute Transporters (FCTs) and RUSSELL High-Pressure Grinding Roll (HPGR) Transporters can be relied on to take the load off. Available in 60 tonne to 110 tonne capacities.

SUSPENSION SYSTEMS

Discover our range of ergonomically safer THUNDERBOLT suspension systems, along with RME Advanced Technology Suspension Systems engineered for higher-reach autonomous knock-in.

Read MoreExplore more RME Mill Relining System technologies

RME ADVANCED TECHNOLOGY

Our relentless pursuit to improve safety and productivity has driven us to engineer a future where relining is performed safely from outside the mill – at faster speeds than ever before.

Read More

RUSSELL CLAW

Introducing the RUSSELL Claw™ – the new master of muck-out. It eliminates hazardous manual liner slinging, enabling worn liner removal with no crew on the charge. Lifting capacity up to 8000 kg.

Read More

RME BOLTBOSS

RME BOLTBOSS is an innovative universal toolset that enables safer securing of liners, nuts and bolts from the mill’s exterior without the need for crew to be inside.

Read More

RUSSELL LINER LEVER

Remove crew from hazardous fall zones with fast and safe removal of stuck worn liners and rubber backing remnants from the mill shell.

Read More

RUSSELL ALL-REACH GRAPPLE

Robust, reliable and RME’s best performing powered grapple yet, the RUSSELL All-Reach Grapple delivers maximum lifting power and precision control. Lifting capacity up to 10 tonne.

Read More

In-mill visibility and lighting technology

Improve in-mill visibility, safety and productivity with RME's range of lighting and vision technology, including the brilliant RUSSELL MILLBRITE In-Mill Lighting and RME EYE.

Read More

RUSSELL MRM asset protection

Compared to the cost of downtime, premature part replacement, repairs or incidents, equipment protection is an easy, economical way to protect your investments.

Read More

THUNDERBOLT accessories

Improve knock-in speed, safety and equipment longevity with our range of THUNDERBOLT accessories and asset protection options.

Read More