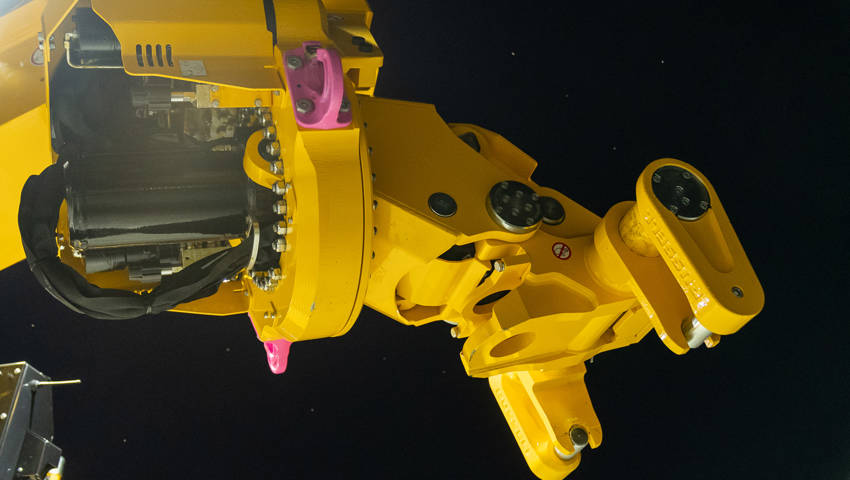

RUSSELL ALL-REACH GRAPPLE

Robust, reliable and RME’s best performing powered grapple yet, the RUSSELL All-Reach Grapple delivers maximum lifting power and precision control. Lifting capacity up to 10 tonne.

The new RUSSELL All-Reach Grapple™

BENEFITS

- Tough, durable and built-to-last quality

- Industry-best safety systems

- Powerful performance with precise control

- High payload capacity – up to 10 tonne

- Works with all liner designs including feed, shell, discharge grates and pulp lifters from leading OEMs

- Improves RUSSELL MRM utilisation, efficiency and return on asset usage

- Increase throughput by the ability to optimise liners resulting in a longer campaign

ADDITIONAL INFORMATION

-

- A RUSSELL 7 Mill Relining Machine features a three-axis grapple fixed to the end of the telescoping boom

- Grapple Slew, Grapple Rotation and Grapple Raise

- Liner Slew, Liner Roll, Liner Raise

- Combined with the other four MRM axes, the RUSSELL 7 MRM can precisely place liners in every mill zone

- The RUSSELL All-Reach Grapple™ offers superior centre of gravity (CoG) for deeper offset liners and higher flexibility and versatility

- Easy to operate for faster relines and increased mill availability

- Enhanced design with durable components with easier removal and fitment of guarding during servicing

- Greater flexibility when choosing MRM capacity – available in 2-pin and 4-pin grapple tools

- Improved construction design increasing reliability

- Engineered for ±70° liner roll motion (140° total) for accurate

liner handling - Increased CoG offset helps future-proof MRM investment – offset improvement of up to 650 mm for higher capacity grapples

- Optimises full performance potential of RME Mill Relining System

- Hydraulic mechanism enables fast and safe liner pick-up,

placement and release - Can feature encoders for future AutoMotion™ upgradeability

- Compact design with hydraulic hoses hidden to minimise crushing impact risk

-

- The RUSSELL All-Reach GrappleTM is purpose-built for RUSSELL Mill Relining Machine

- With an engineering assessment the RUSSELL All-Reach GrappleTM can be retrofitted onto many existing RUSSELL 7 & 8 MRMs

- Ready for use on all RUSSELL 7 MRMs from 2024 onwards

- Retrofits required for RUSSELL 7 and 8-axis MRMs pre-2023

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs engineered, manufactured and delivered.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME assets & services.

"The new and improved RUSSELL All-Reach GrappleTM is designed to manage heavy and deep liners effortlessly and tackle difficult mill conditions. With five models available, it’s the perfect complement to any RUSSELL Mill Relining Machine. Plus, it provides future-proofed compatibility with RME AutoMotionTM, RME INSIDEOUTTM Technology, and RUSSELL ClawTM compatibility, guaranteeing maximum productivity and safety by relocating operators outside the mill during relining procedures."

Related products

RUSSELL CLAW

Introducing the RUSSELL Claw™ – the new master of muck-out. It eliminates hazardous manual liner slinging, enabling worn liner removal with no crew on the charge. Lifting capacity up to 8000 kg.

Read More

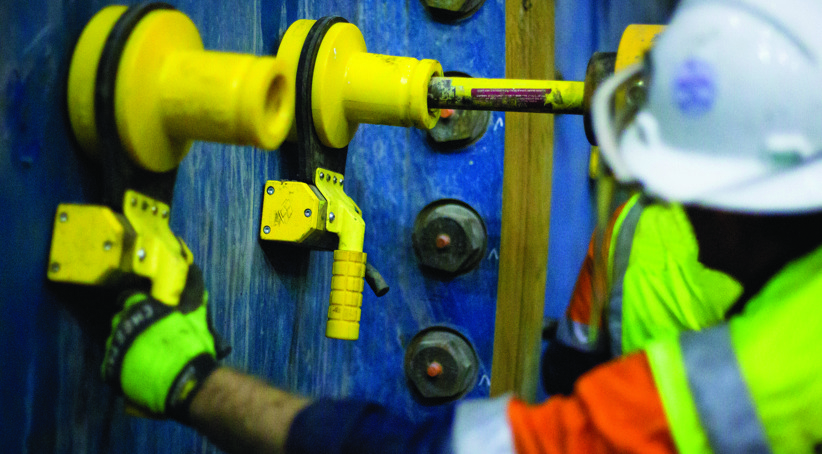

RME BOLTBOSS

RME BOLTBOSS is an innovative universal toolset that enables safer securing of liners, nuts and bolts from the mill’s exterior without the need for crew to be inside.

Read More

RME EYE

The RME EYE Visibility Camera System improves the MRM operator’s view of critical work areas and reduces the risk of person and operating mobile plant interactions.

Read More

THUNDERBOL T-MAG MOIL ACCESS GUIDES

T-MAGs are designed for use with THUNDERBOLT Recoilless Hammers to make liner bolt knock-in safer and more efficient, and protect the mill shell.

Read MoreSS&O Sales Team

Owen Flemming

Regional General Manager, North/Central America, Leadership Team

Denny Wisely

Vice President Sales & Business Development, North America

Manuel Galvez

Regional General Manager, South America, Leadership Team