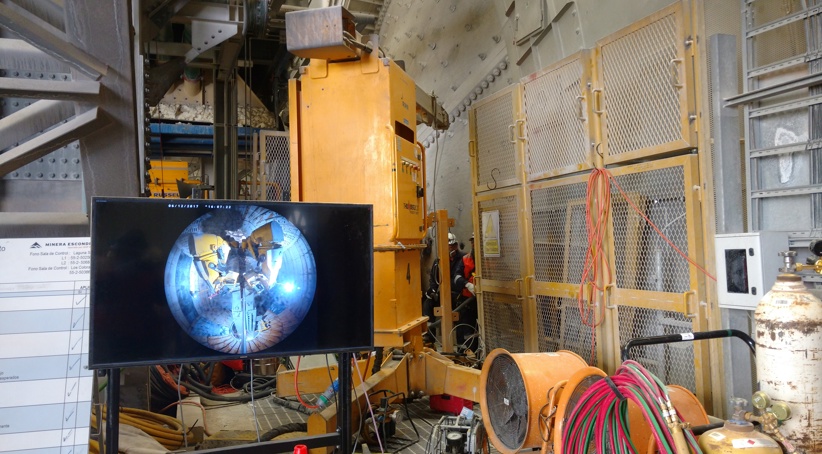

RME EYE

The RME EYE Visibility Camera System improves the MRM operator’s view of critical work areas and reduces the risk of person and operating mobile plant interactions.

RME EYE Visibility Camera System reduces the risk of safety incidents and increases mill visibility. RME EYE combines quality and reliability to improve the operator’s view of critical working areas that are not visible from the operator’s console. The visibility camera system is expertly-engineered for easy, durable operation even in the harshest of conditions.

BENEFITS

- Provides operator confidence in monitoring personnel movements in the mill

- Superior camera system positioned for operator comfort

- Easy to use with minimal set-up and configuration

- Significantly reduces risks to personnel working in close proximity to the RUSSELL Mill Relining Machine (MRM)

- Higher levels of safety in hazardous areas

- Increases reline productivity and mine site profitability

ADDITIONAL INFORMATION

-

- High intensity screen with impact-resistant polymer protective cover for safe storage

- Engineered with an IP68 rating for harsh operating environments

- Adjustable screen positioned for better ergonomics

- Low latency cameras automatically adjust to low light

- Durable display system can operate in temperatures of up to 60˚C

- Installed with a light pole or replaceable with one that has a camera

- Fully powered by the RUSSELL MRM with no additional power source required

- Camera mounting position is safely stowed between relines

- Forward camera is focussed on the obscured working zone opposite to operator

- Camera feeds uniquely displayed on the all-in-one screen

- Robust connections for reliability and longevity

-

- Replaces fixed MRM mirrors that have a very limited range of view and poor clarity in low light conditions

- Available for RUSSELL 7 and RUSSELL 8 MRMs with a single or dual seat arrangement option and RUSSELL TWIN MRMs

- Bundle option available with a RUSSELL MILLBRITE or LED Lighting Upgrade

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs engineered, manufactured and delivered.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME assets & services.

"The distinct advantage of RME EYE is the ability to spot those close to the RUSSELL MRM in potentially dangerous situations, so that the operator can take fast action to prevent injuries."

Related products

RUSSELL 7-S MRM

Signature performance and the industry’s most widely adopted mill relining machine.

Available in 2500 kg – 10 tonne capacities.

RUSSELL 3/7-E 1500 Hybrid MLH/MRM

Can be either – a 3-axis handler that evolves to a 7-axis MRM – to advance relining speed and safety.

1500 kg capacity

THUNDERBOLT MAGNUM 1000

The THUNDERBOLT MAGNUM 1000 is the industry's most productive hammer yet. It's high-energy rapid-fire rate will shorten knock-in times and improve operator safety.

Read More

RUSSELL MILL SURVEILLANCE

RUSSELL Mill Surveillance is a real-time camera feed that helps mill operators monitor the progress and safety of their mill relining operations.

Read MoreSS&O Sales Team

Owen Flemming

Regional General Manager, North/Central America, Leadership Team

Denny Wisely

Vice President Sales & Business Development, North America

Manuel Galvez

Regional General Manager, South America, Leadership Team