WE ARE RME

RME is the world's most trusted original equipment manufacturer (OEM) of mill relining technologies. Our mission is to reduce hazardous risk and improve the availability of mineral concentrators.

Trust RME to raise the standard

Trusted for almost 40 years as the global leading manufacturer and supplier of fast, reliable, safe, mill relining technologies, asset support and optimisation services.

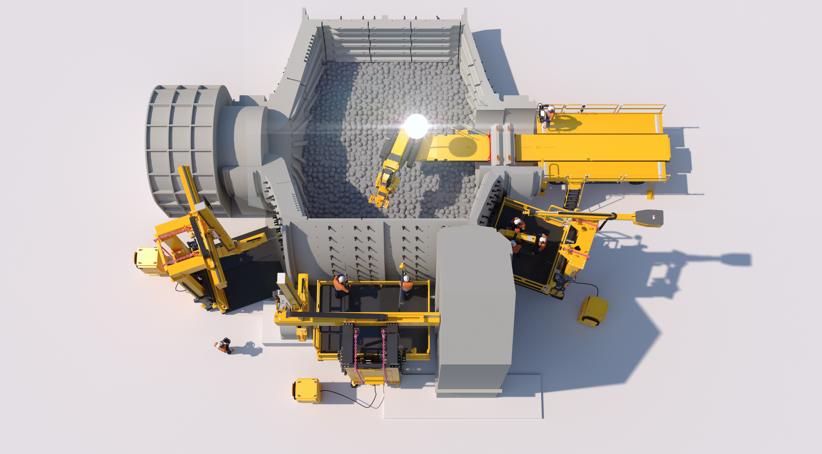

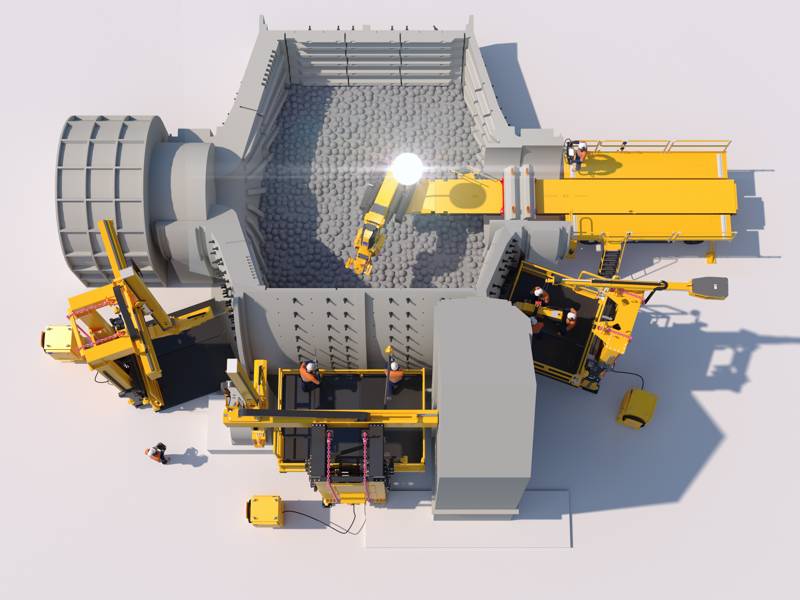

The RME Mill Relining System is the preferred choice for mill operators globally. And now it is ready for an even faster, safer automated future.

Read More

With over 40 years of OEM expertise in improving grinding mill relining, RME has revolutionised crusher head nut changeouts. Our innovative solution eliminates risks, improves speed and enhances safety.

Read More

Tap into OEM expertise, performance benchmarking and advanced technologies to guide your operations to improved concentrator performance and relining safety – measurably, repeatedly, sustainably.

Read More

Improve the speed and safety of your RME Mill Relining System with INSIDEOUT™ Technology, AutoMotion™ and grapple upgrades, and our wide range of equipment accessories.

Read More

Ensure mill relining equipment safety, productivity and longevity with RME's regionally-based inspections and servicing, critical spares provisioning and certified training.

Read More

With our 35+ year supply to mine sites globally and 90% of our MRMs still operating, we provide trusted insights on component wear rates and support for spare parts.

Read MoreMineral processors need to address issues that are more challenging and more urgent than ever.

On one hand they must reduce the risks that remain associated with hazardous mill relining. On the other, maximise mill availability for meeting the world’s mineral needs.

It is this pursuit to improve safety and productivity that drives RME to innovate for our industry.

This has led us to envision a future where relining is performed with no one inside the mill, an environment that allows us to accelerate the machines and reline at faster speeds than ever before.

And now this future is here.

RME is the world's most trusted original equipment manufacturer (OEM) of mill relining technologies. Our mission is to reduce hazardous risk and improve the availability of mineral concentrators.

Join our global team of diverse and inclusive people engineering innovative solutions that aspire to improve the human condition through responsible access to metals at lower cost.

We ensure Customers have access to trusted OEM engineering know-how where and when they need it. Here's how to contact RME.

RME's Integrated Management System Scope

The RME Quality, Safety and Environmental Management System is integrated and certified in accordance with ISO 45001, ISO 14001 and ISO 9001. This includes the engineering, production, Customer support and service of specialist mining and mineral processing equipment in Toowoomba. The RME Integrated Management System contains no exclusions. International Sales and Service Centres form part of the RME Management System with the view of future inclusion into the RME Australia scope for individual certification. For more information on RME's commitment to Quality, Safety and Environmental and our Company Directives, please see HSWQ Policies by clicking here.