04 May 2021

RME set to revolutionise mill liner maintenance again with THUNDERBOLT SKYWAY

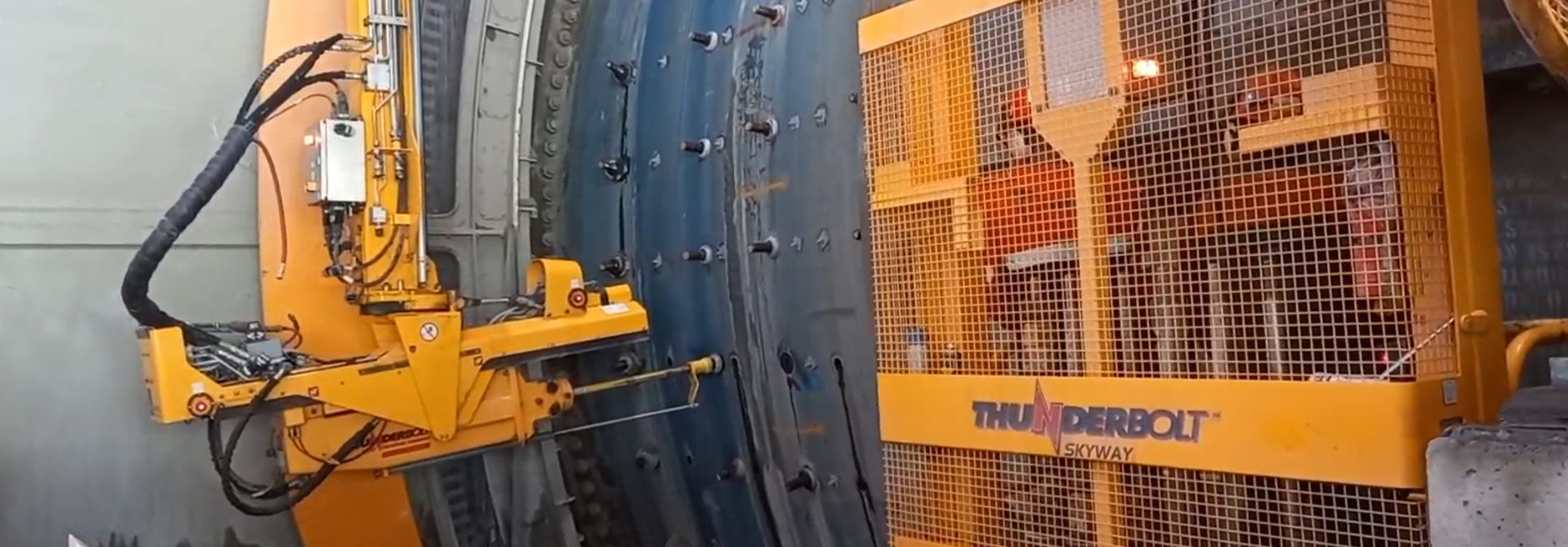

THUNDERBOLT SKYWAY, a semi-automated suspension, guidance, and firing system for THUNDERBOLT Recoilless Hammers and elevating work platform modules was featured in an article by International Mining.

THUNDERBOLT SKYWAY is an innovative new semi-automated suspension, guidance and firing system for THUNDERBOLT Recoilless Hammers – including MAGNUM, from Australia’s RUSSELL MINERAL EQUIPMENT (RME).

These hammers are used for worn grinding mill liner bolt removal, an intensive process commonly referred to by the industry as ‘knocking-in.’ These difficult-to-dislodge bolts are part of the mechanism that secure the mill liners to the internal shell of the mill.

Traditionally, reline crews would manually guide recoilless hammers into position on the outside of the mill, fire, manually move to the next bolt and repeat. However, with SKYWAY, hammers are suspended from a gantry system that is contoured to the shape of the mill, guided into position and fired by remote control.

Following the recent successful application of the system on a customer SAG mill, IM Editor, Dan Gleeson, got the lowdown on the technology and its potential from RME.